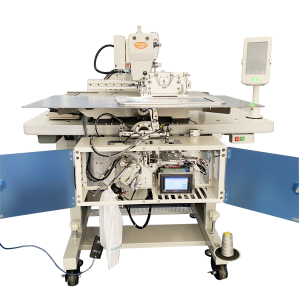

Inserting Shoe Eyelet Sewing Machine CC-3020G-02A-ZD

Inserting Shoe Eyelet Sewing Machine CC-3020G-02A-ZD

| Model | CC-3020G-02A-ZD |

| Sewing area | Max.30×20cm |

| Line | single needle sewing |

| Highest sewing speed | 2700rpm |

| Feeding device | Intermittent feeding (pulse motor driven mechanism) |

| Stitch length | 0.05-12.7mm |

| Max.stitches | 20,000 stitches/pattern |

| Work clamp lifter | pneumatic (height:max.30mm) |

| Clamp lifter | divided |

| Clamp lifter ascension range | 22mm |

| Hook | double shuttle hook (Hirose Janpan) |

| Belt | Opti Germany |

| Sensor | Omron Japan |

| Valves | SMC Japan |

| Tension device | electric tension device optional |

| Data storage | USB or Memory card(CF card can save and edit any sewing patterns) |

| Motor | AC servo motor 550W |

| Air pressure | 0.5Mpa 1.8L/min |

| Net weight | 220kg |

| Gross weight | 290kg |

| Packing | 125*90*135cm |

| CBM | 1.52m³ |

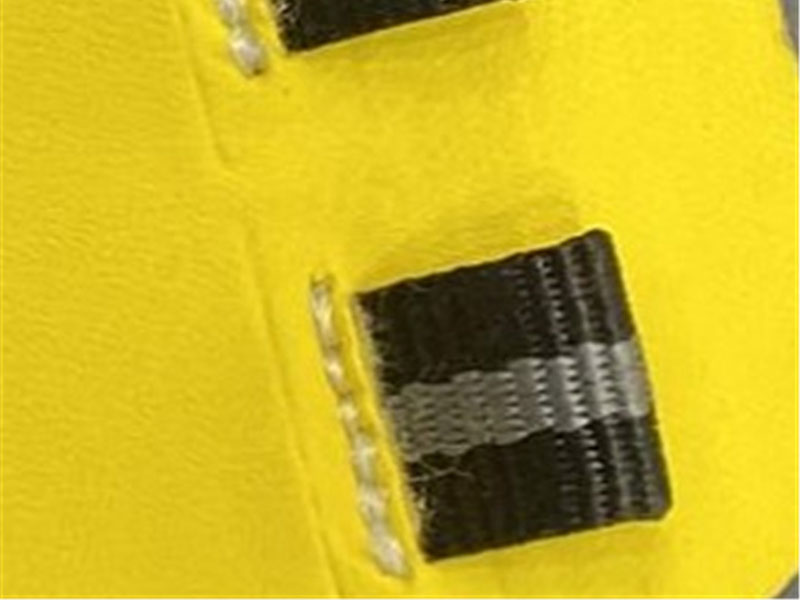

Automatic sewing machine specialized in eyelet webbing sewing of sporting shoes traditional working process including cutting the webbing, punching the eyelet, feeding the webbing by hand, then sewing, need at least 3-4 workers.

Use this machine can finish all the work process by automatic cutting, punching, feeding and sewing.

It can improve the productivity and save around 70% labor cost, the standard finished product avoid the difference which could happen by manual sewing machine

Footwear sewing machine specialized in sewing the sports shoe upper, climbing boot, outdoor shoes, gym shoes, casual shoes, with the automatic feeding system to attach the shoelace loop and shoe tongue loop sewing. Manipulator conveying the materials, cutting and sewing automatically.