Computerized Pattern Sewing Machine CC-3020 / 3525G-01A

Computerized Pattern Sewing Machine CC-3020 / 3525G-01A

| Model | CC-3020G-01A |

| Sewing area | Max.30×20cm |

| Line | single needle sewing |

| Highest sewing speed | 2700rpm |

| Feeding device | Intermittent feeding (pulse motor driven mechanism) |

| Stitch length | 0.05-12.7mm |

| Max.stitches | 20,000 stitches/pattern |

| Work clamp lifter | pneumatic (height:max.30mm) |

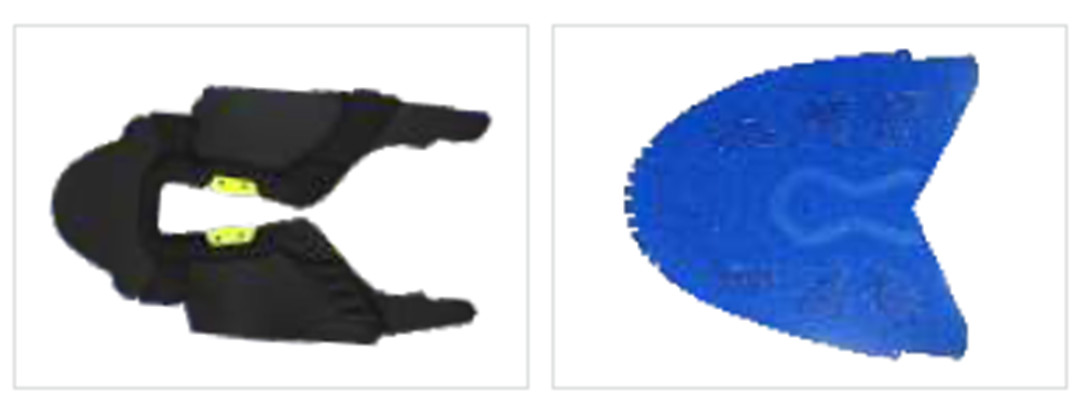

| Clamp lifter | divided |

| Clamp lifter ascension range | 22mm |

| Hook | double shuttle hook (Hirose Janpan) |

| Belt | Opti Germany |

| Sensor | Omron Japan |

| Valves | SMC Japan |

| Tension device | electric tension device optional |

| Data storage | USB or Memory card(CF card can save and edit any sewing patterns) |

| Motor | AC servo motor 750W |

| Air pressure | 0.5Mpa 1.8L/min |

| Net weight | 230kg |

| Gross weight | 320kg |

| Packing | 126*126*135cm |

| CBM | 2.2m³ |

According to the requirements of the product can realize the multi - section thread tension adjustment, so that the sewing stitch is more beautiful. Moreover, simple embroidery patterns can be sewn, which is difficult for ordinary embroidery machines to perform on thick fabrics.

When the thickness of the fabric changes, the intermittent pressure foot can be switched, so the intermittent pressure foot always acts according to a certain intermittent pressure. Can prevent presser foot to lift too high or too low so as to realize up and down line consistent sewing.

Without using tools, you can set the pressure foot rise by entering a value on the panel or in the program. In addition, depending on the sewing procedure, the height of the intermittent presser foot can be set to the desired height using a user program